Connected Fire Cylinder Monitoring measures the pressure and temperature of FM-200 / Novec 1230 and Inert gas system cylinders, sending data wirelessly to the cloud. The Cylinder data is analysed if errors are detected then the system notifies you giving information to allow you to take action.

Connected Fire Container Monitoring is fully addressable. It will give specific data for each container in the system, rather than simply providing a low pressure alarm. This helps limit low pressure false alarms which may be due to changes in temperature as opposed to an actual loss in pressure.

Conventional cylinder pressure switches often simply use a common fault indication on the system control panel.

By connecting pressure and temperature, low pressure conditions that could be due simply to low temperature are normalised, avoiding fault conditions being recorded and the need for unnecessary intervention.

Microleak detection allows notification before system integrity is compromised and allows for scheduled intervention, minimising cost of repair and system down time.

Connectivity of a remote monitoring device is a helpful technology, giving steady and reliable monitoring of data. This will result in a significant enhancement in the systems overall performance/reduction of man-hours, while achieving the optimum response time and corrective action that may be needed. Thanks to the significant real-time reporting, the corrective actions can be taken immediately, which is great for those facilities and systems not easily accessible.

How it Works

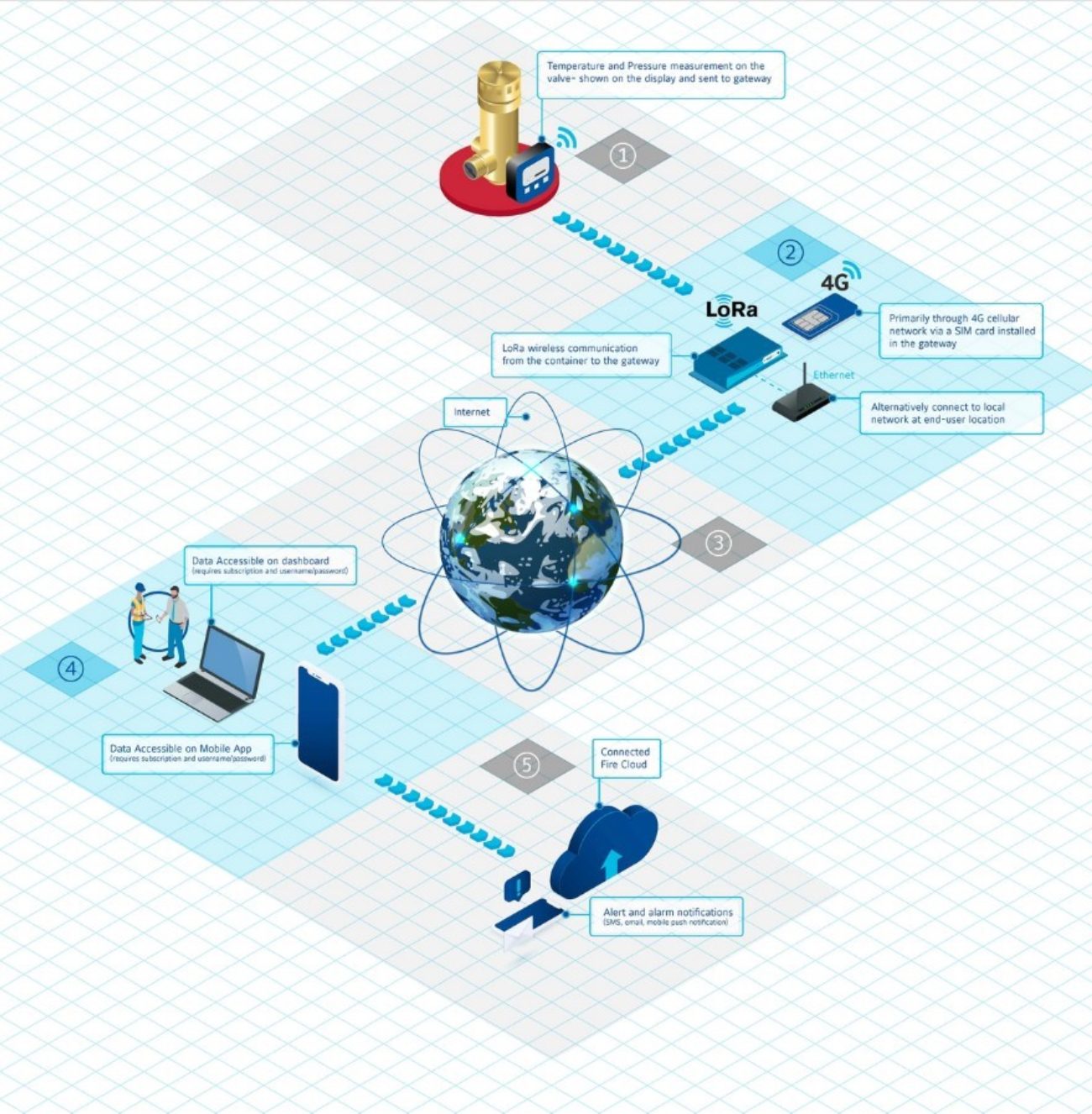

The Connected Fire Cylinder Monitoring device collects data from each fire suppression cylinder at set time intervals chosen during configuration. It can connect to a mobile device such as a smart phone or tablet, sharing information in real time on an online dashboard.

It can be accessed anywhere in the world at any time of the day or night, allowing for speedy intervention in the case of a low-pressure fire suppression cylinder (that is not temperature related) before it compromises the fire suppression system. It is powered by a battery that has constant health monitoring displayed on the dashboard.

Backwards Compatibility

Backward compatible for field retrofits on most existing systems. Contact us to confirm your system compatibility.

Key Features

- For use with Novec 1230 & Inert gas Such as IG-55 or Inergen Suppression Systems

- Remote monitoring of cylinder pressure and temperature

- Cylinder data viewable by service contractor and end-user anywhere with access to internet or cellular network

- Early warning of low pressure in an individual cylinder

- Configurable microleak detection analysis and notification

- Communication protocol to the cloud via cellular network or local network

- Up to 2 year battery life operation with intelligent low battery operation, preventing connection interruption

- Dashboard provides document storage for system design documentation along with system installation photos

Applications

- Hyperscale Data Centres (Cylinder Storage Rooms)

- Colocation Facilities

- Enterprise Data Centres

- Edge Data Centres

- Comms Rooms

- Server Rooms

- Battery Rooms

- Cloud Data Centres

- Modular Data Centres

- Mobile Phone Sites

- Remote or Unmanned Sites

Do you have a technical question?

Call us on 01628 902107 or email [email protected]